Empowering Safety Through Precision and Innovation

FINAL Tank

The FINAL test system offers an innovative approach to evaluating the power and time performance of airbag inflators. Focusing solely on the inflator component, the results of the FINAL test system reflect the same performance differences observed in sled and crash tests. This makes compliance testing for the inflator component now possible.

Designed for airbag substitution in vehicle safety part production or aftermarket applications, the FINAL test system serves as a reliable, valid, and cost-effective qualification tool.

The data generated by the FINAL test system provides significantly more valuable feedback to the CAE simulation department compared to traditional tank test results, enabling improved simulation accuracy and decision-making.

- Available Sizes:

- 15/25 L

- 60 L

- 90 L

- 120 L

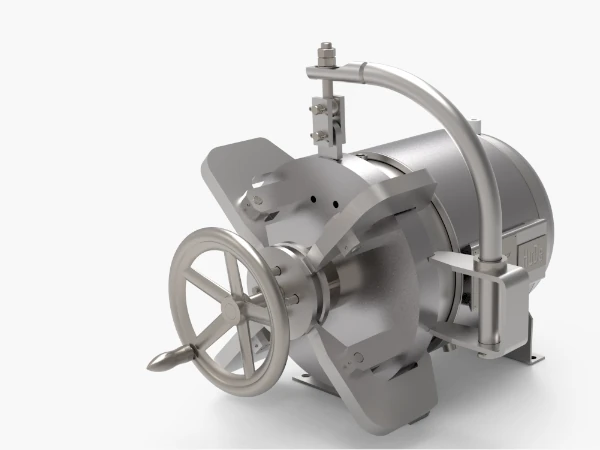

Tank Test

The HuDe Tank Test enables reproducible testing of gas generators and inflators under controlled and safe conditions. The test object is securely fixed inside an airtight pressure tank and ignited. The resulting gas creates a pressure curve, which is precisely measured, evaluated, and analyzed according to all standard methods (e.g., AK-LV, USCAR, etc.).

The tank volume, test item adaptations, sensors, and testing software are customized to meet the specific requirements of each customer, ensuring tailored solutions for every test scenario.

- Available Sizes:

- 28.3 L

- 60 L

- 120 L

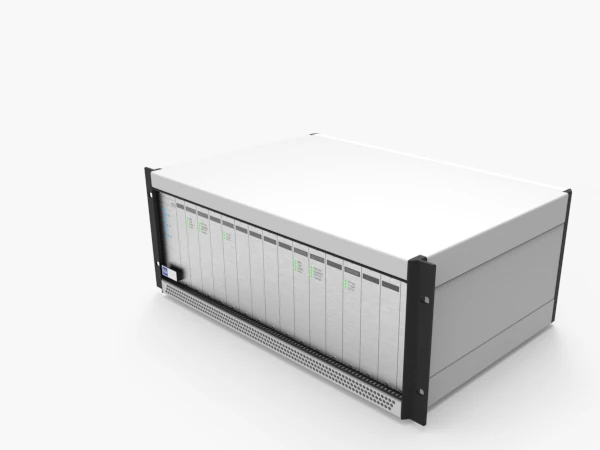

Thermal Transient Tester / Ignition test

HuDe Thermal Transient Testers are utilized in the assembly line of fuses for quality assurance. The ignition of the ignitor occurs through ramping in the NoFire area. The thermal transient effect generated during energization is precisely recorded and evaluated.