Empowering Safety Through Precision and Innovation

Revamping

The resource-efficient utilization, maintenance, and modernization of existing systems and machines are becoming increasingly important. As a dedicated service provider, HuDe offers customized revamping solutions for track-bound special vehicles tailored to individual customer needs.

Our expertise spans electrical engineering, mechatronics, and the modernization of automation technology, software, and visualization systems, ensuring optimized performance and extended operational lifespan of your machinery.

The HuDe Track Measurement System is a portable solution designed for seamless installation on existing track vehicles. It enables non-contact rail head measurement for accurate determination of track geometry and position.

Measurements can be conducted at speeds of up to 200 km/h, ensuring efficient and precise data collection during operation.

Test Bench for Current Collectors

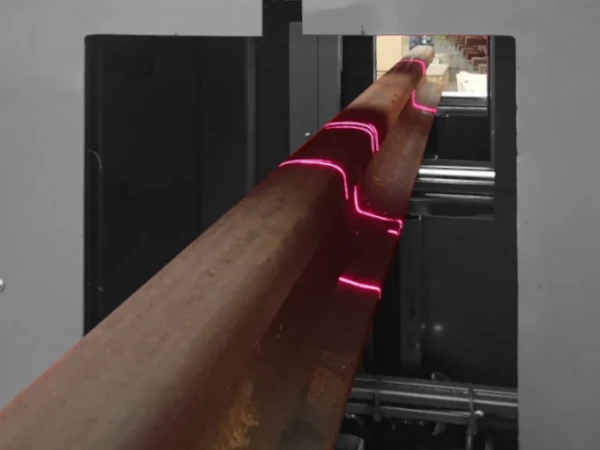

The Surface Inspection System OIS is designed for final quality control in rail rolling mills. Every rail produced undergoes a fully automated, laser-assisted surface measurement to ensure precise inspection.

Powered by highly efficient software algorithms and advanced PC technology, the system enables real-time analysis and evaluation. In addition to inspecting the track surface, it also recognizes and evaluates stamped serial numbers and characters, ensuring complete quality verification.

Surface Inspection System

The Surface Inspection System is designed for final quality control in rail rolling mills. Every rail produced undergoes a fully automated, laser-assisted surface measurement to ensure precise inspection.

Powered by highly efficient software algorithms and advanced PC technology, the system enables real-time analysis and evaluation. In addition to inspecting the track surface, it also recognizes and evaluates stamped serial numbers and characters, ensuring complete quality verification.

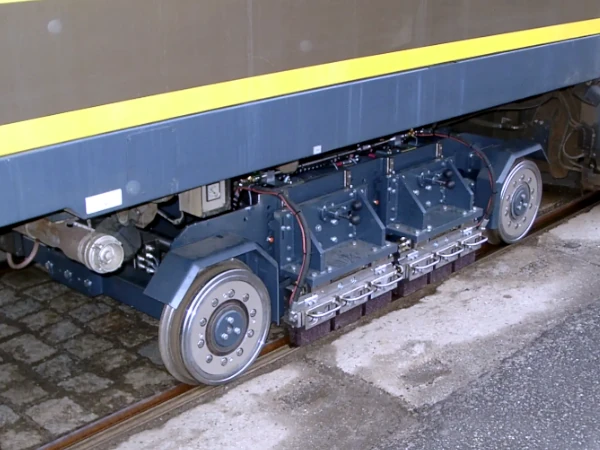

Grinding machines

HuDe grinders are designed for the efficient machining of rail surfaces, aiming to reduce noise and enhance driving comfort for users of mass transit systems. These grinding machines can be integrated with both new and existing carrier vehicles.

In addition to slide stone grinding, optional oscillating grinding is also available. The machines are compatible with various types of grindstones to suit specific needs. Furthermore, the high-pressure cleaning system reduces maintenance requirements and minimizes pollution, ensuring long-term operational efficiency.