Empowering Safety Through Precision and Innovation

Airbag Testing Laboratory

The HuDe airbag test laboratories are equipped with state-of-the-art technology to meet the latest test standards, ensuring all requirements are seamlessly covered by our ignition system and DAQ / Interfacer. With an interface that can now be expanded to 8 ignition channels, multiple test stations can be controlled independently.

The entire time, test, ignition, and detection system is managed by a single unit: the HuDe Interfacer, which is currently in use across more than 160 independent testing laboratories. This integrated approach streamlines operations and ensures precise and reliable testing.

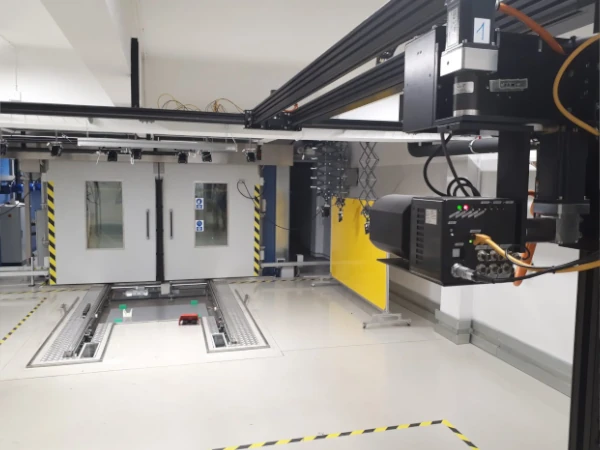

Positioning systems

In airbag testing, video quality and reproducibility are critical for accurate results. That’s why a range of solutions is designed to simplify or even fully automate camera settings.

Starting with manual camera positioning systems that provide cost-effective support for camera setup, to advanced fully automated solutions ensuring precise adjustments of multiple cameras across all axes (X/Y/Z), as well as pan, tilt, and lens settings (including aperture, zoom, and focus), every aspect is addressed.

Camera positions can be taught in using a 3D controller and stored in modern databases as customized test configurations. Switching between test scenarios becomes effortless, done with just one click, ensuring maximum reproducibility for every test.

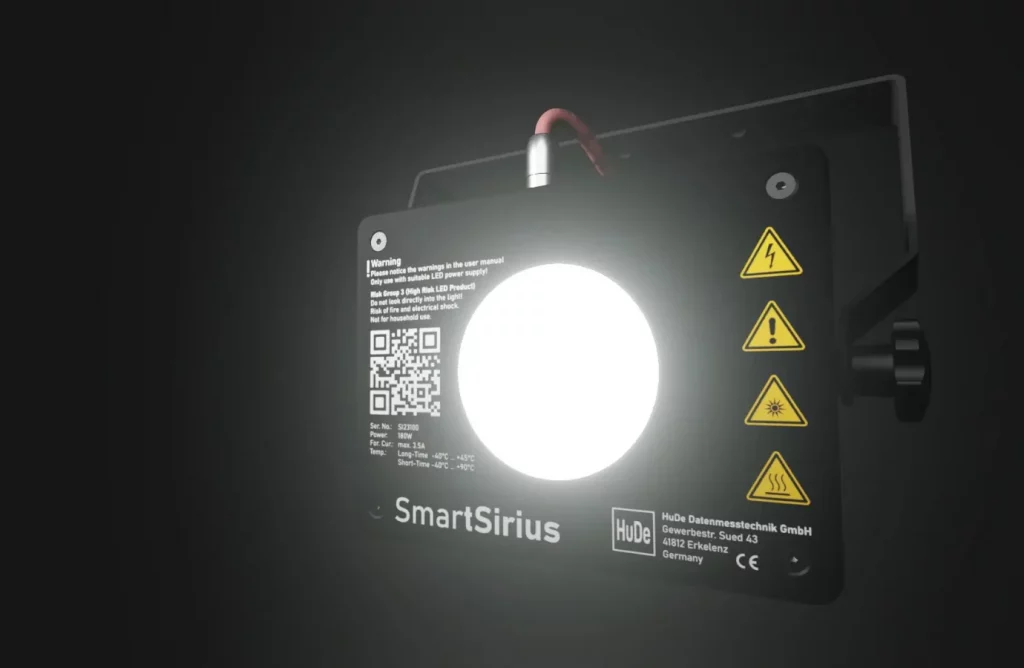

Lighting systems

To capture contemporary, high-quality high-speed videos, a variety of lighting concepts and systems are available. In addition to conventional halogen and HMI luminaires, state-of-the-art LED lighting technology is offered for use in RT/Ambiente tests as well as for testing in climate chambers.

A broad range of ceiling mounting systems, tripod solutions, and brackets for all types of luminaires is also included in the portfolio.

The control and integration of all available lighting systems into the overall system is essential, ensuring seamless operation and consistent performance across all test setups.

Software

As the interface between the user and the test systems, the software plays a key role in ensuring seamless operation. Through continuous development and the ongoing expansion of its functionality, the software offers a wide range of interfaces to third-party systems, such as nearly all popular high-speed cameras, lighting systems, and climate chambers.

Data export is supported in various formats (e.g., Excel, DIAdem, ISO-MME, ASCII, JPG, AVI), with new formats continually added to meet evolving needs.

The software efficiently manages all integrated components within the system, ensuring smooth coordination. The philosophy is simple: One PC and one software for everything – turn-key!

Just as unique as the customers and their system requirements, the software is fully customizable to suit specific needs.

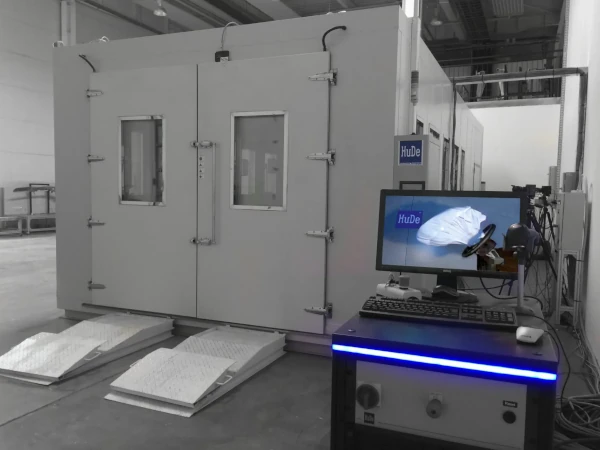

Climate chambers

The automatic climate chambers allow for the storage of test specimens at temperatures ranging from -50°C to +120°C. The transfer of the test specimen to the testing position is facilitated by an integrated shuttle transfer system, capable of handling a maximum load of up to 400 kg. Both the transport and the subsequent airbag test are completed within the required withdrawal time of a maximum of 10 seconds.

Thanks to the compact interior volume and the chamber door, which partially closes during the test, the system not only ensures energy savings but also achieves significantly faster tempering times, optimizing test efficiency.