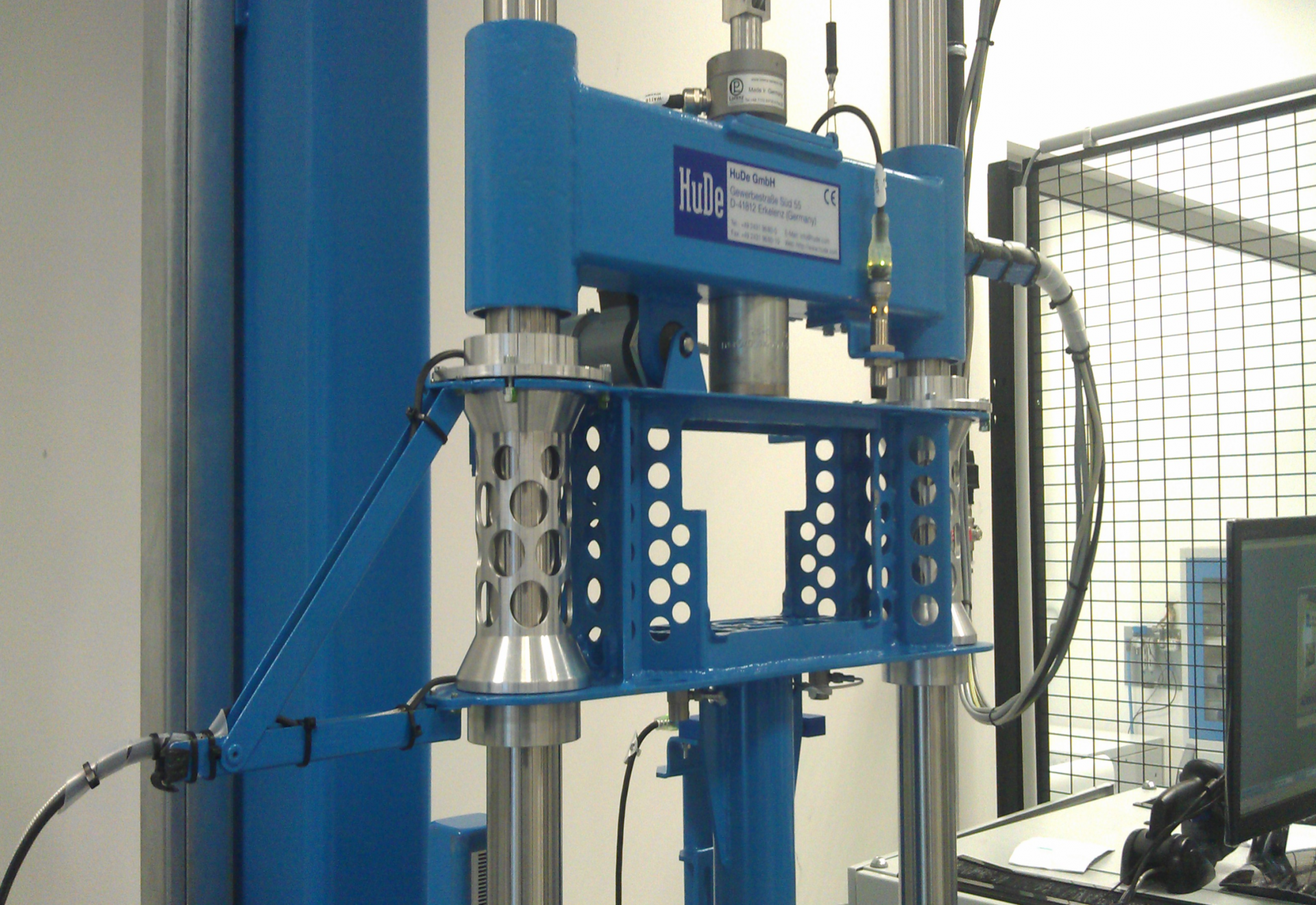

Drop Tower Test System

The Drop Tower Test System designed by HuDe is perfectly suitable for the integration in test facilities. It´s mainly used for testing of instrument panels (IPs) without deploying procedure.

All instrument panel supplier and manufacturer can have an end of line quality check with our system. In general a sample of lot can be directly tested and confirmed before following upcoming processes. With our system you are able to control your production and reduce testing costs.

We have different variations and approach for IP fastening. You can choose the DTTS with an A-sided or B-sided fastening.

The HuDe measurement equipment provides test data like acceleration, speed, force, deformation during impact and room temperature as well as surface temperature of the IP. The data can be edited with the HuDe software.

Drop Tower Test System

The Drop Tower Test System designed by HuDe is perfectly suitable for the integration in test facilities. It´s mainly used for testing of instrument panels (IPs) without deploying procedure.

All instrument panel supplier and manufacturer can have an end of line quality check with our system. In general a sample of lot can be directly tested and confirmed before following upcoming processes. With our system you are able to control your production and reduce testing costs.

We have different variations and approach for IP fastening. You can choose the DTTS with an A-sided or B-sided fastening.

The HuDe measurement equipment provides test data like acceleration, speed, force, deformation during impact and room temperature as well as surface temperature of the IP. The data can be edited with the HuDe software.

Free Fall

With our free fall design system, we obtain reproducible values. As long as the shafts and the slide bearings are matched, we achieve a high efficiency of about 97 % and a fall height of up to 2,200 mm according to impact point.

Free Fall

With our free fall design system, we obtain reproducible values. As long as the shafts and the slide bearings are matched, we achieve a high efficiency of about 97 % and a fall height of up to 2,200 mm according to impact point.

Impact Energy

The HuDe system provides the evaluation and energy calculation via either the 1-axis load cell or the integrated acceleration sensors. With an adjustable drop height up to 2,200 mm to the impact point and corresponding weight adjustment from 8 kg to max. 20 kg, can you realize energies from 160 J up to 400 J with this system.

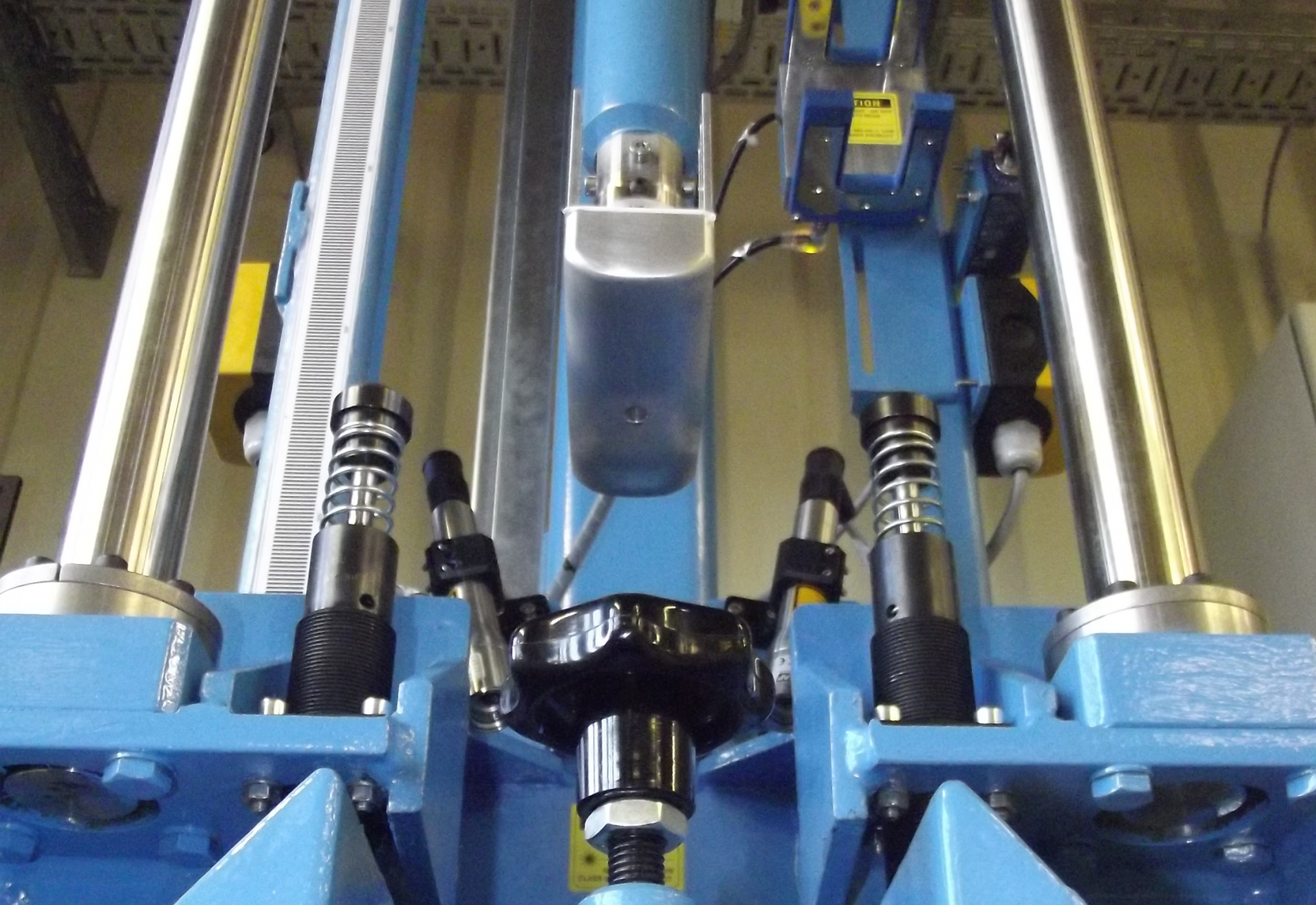

Acceleration

Measurement

The sensors detect accelerations and decelerations. The entire signal curve reflects the time energy consumption of the experiment, which can also calculated (integration). Through the use of two sensors, changes in load due canting of the test object, can be compensated by averaging both signals.

Force

Measurement

The force sensor is integrated next to the impact head. It´s basically designed as a strain gauge sensor. A advantage is the near position to the impact and the low sensitivity to vibrations. Filter retreatment is not mandatory. In addition, the calibration is veri-fiable by a simple weight load. The evaluation of the force curve is given without conversion.

Speed

Measurement

For this measurement two different sensor types are used. Light barriers and a digital position measuring system. The adjustable v-measuring at the impact point is realized with a variable light barrier block. The optical displacement sensor (incremental path measuring method) can also be used for v-measuring with a resolution of approx.1mm.