Static Deployment Test System

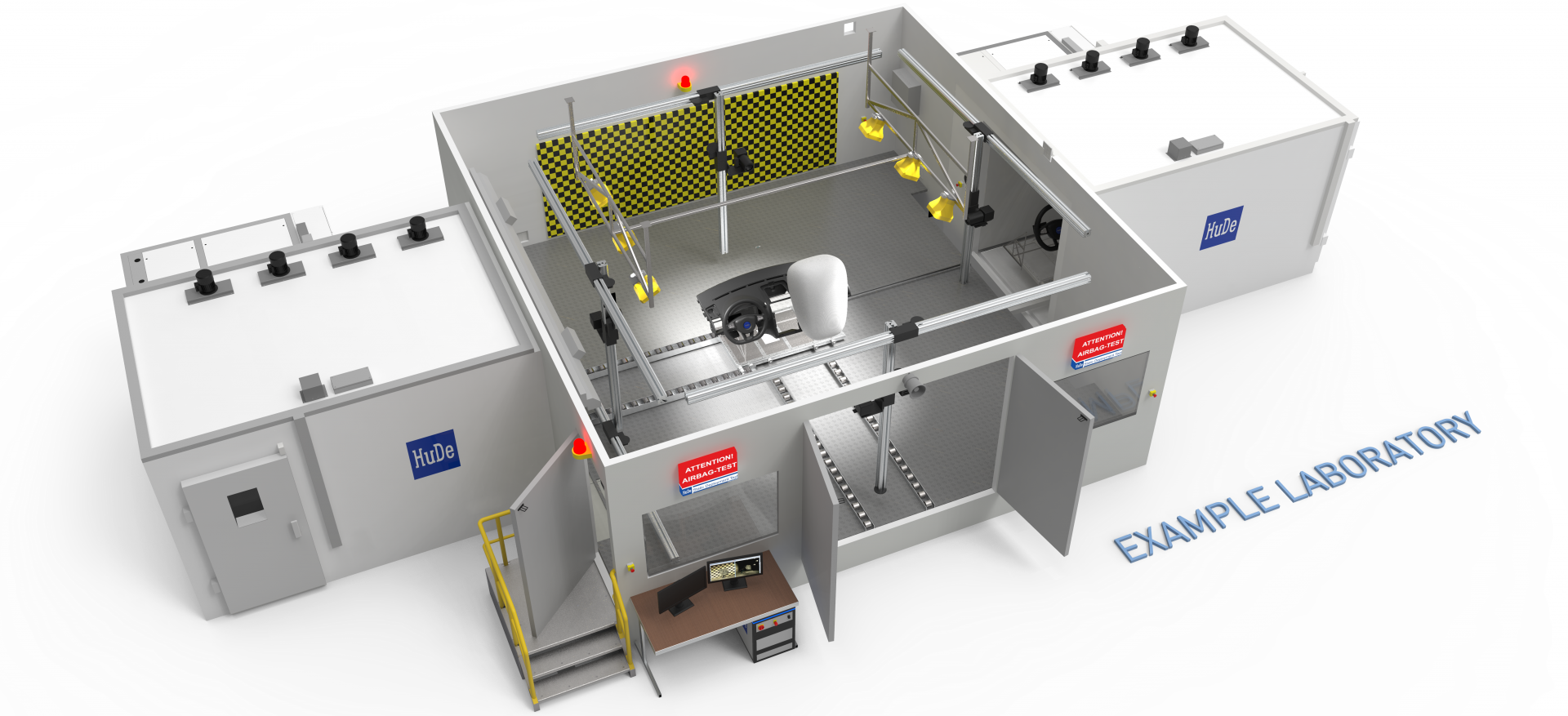

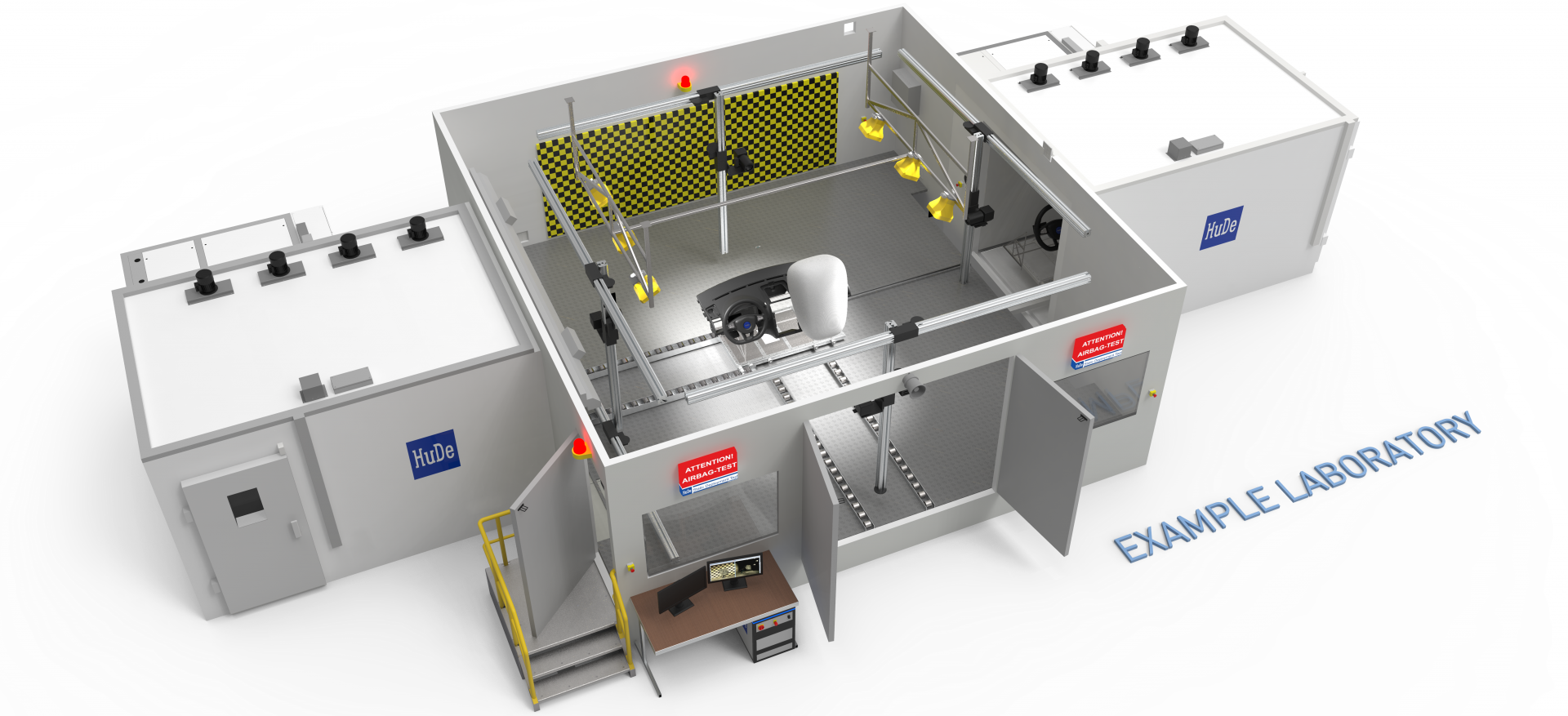

Nowaday airbag test systems are an integral part of all manufactured cars. These passive safety systems must pass a variety of tests before they can be installed in vehicles. Most attempts are made by destructive tests and accompany all phases of the production of an airbag. The static test facility can be also used for quality inspection of mounted airbag modules. This method uses the Static Deployment Test (SDT), which is explained below as a modular system. The solution for an integrated airbag test facility is based on HuDe’s modular design concept and scalable in a wide range. All tests are processed in accordance with AK-LV specification (Arbeitskreis Audi, BMW, DC, VW) and based on international regu-lations SAE J211, ISO 12097, ISO/TC 13499 and other. The systems are prepared for real temperature testing in range of –35°C to +85°C with optionally extended ranges.

Static Deployment Test System

Nowaday airbag test systems are an integral part of all manufactured cars. These passive safety systems must pass a variety of tests before they can be installed in vehicles. Most attempts are made by destructive tests and accompany all phases of the production of an airbag. The static test facility can be also used for quality inspection of mounted airbag modules. This method uses the Static Deployment Test (SDT), which is explained below as a modular system. The solution for an integrated airbag test facility is based on HuDe’s modular design concept and scalable in a wide range. All tests are processed in accordance with AK-LV specification (Arbeitskreis Audi, BMW, DC, VW) and based on international regu-lations SAE J211, ISO 12097, ISO/TC 13499 and other. The systems are prepared for real temperature testing in range of –35°C to +85°C with optionally extended ranges.

Testing

For test principle two basic procedures are, testing inside and testing outside of climate chambers. The test systems for inside chamber testing typically has the necessary lights in the chamber. These lights are activated very short before the specimen is fired so the temperature change is minimal.

Test objects can be:

- Steering Wheels – with DAB (driver airbag)

- IP – instrument panels with PAB

- SAB – side (seat) airbags

- IC – inflatable curtains

- And many more…

Testing

For test principle two basic procedures are, testing inside and testing outside of climate chambers. The test systems for inside chamber testing typically has the necessary lights in the chamber. These lights are activated very short before the specimen is fired so the temperature change is minimal.

Test objects can be:

- Steering Wheels – with DAB (driver airbag)

- IP – instrument panels with PAB

- SAB – side (seat) airbags

- IC – inflatable curtains

- And many more…

Control System

The operation and data acquisition system controls several functions.

- Single, double and multi stage airbag-ignition with precise delay

- Fully integrated high speed camera

- Camera positioning system

- Test stand lighting in various groups

- Shuttle control to move test targets

- Control for ventilation system

- Control for temperature chamber opening

- Door lock for test room

- Optional temperature monitoring

Software Apps

UNICam

MultiVid

SNIP-PIC-Modul

Synchronized Video and Data

Synchronization tool for a detailed correlation bet-ween video and data accor-ding to same frame rate.

Video Evaluation Tool Box

Video tools for different evaluation operations as area measurement, object tracing, edge deteciton, etc.

HuDe Web-App

System live control over a tablet device with wifi access. Compatibel to common browsers.

Camera Positioning System (CPS)

The CPS is a modular rail and drive system that can be adjusted to the facility layout in a few simple steps. Areas of interest, test room dimensions and obstacles such as pillars and beams are taken into account to make a real 3D simulation of the future CPS configuration. The final result is an automatically adjusted multi-axis motion system that provides highly precise linear and angular positioning of several cameras. The CPS can be attached to the ceiling of the test area or fixed on the floor or the ceiling of

a climate chamber.

Isolated Test Area

Light System

Interfacer

SmartNotify

With our own developed ignition switch, HuDe systems are able to combine and control different test areas with only the Interfacer. At the customized software you can choose the test area as well as configure independently the required setup.

For any kind of errors the SmartNotify started our visual error line. Followed with the Smart Ignition Box our products are prepared for easy handle and visual check of correct operator setup.

- Blue: Neutral mode

- Green: Ready to perform

- Red: Test in progress

- Red, Flash: Emergency stop situation